Eventually I will paint the bus in the reverse color scheme of the MM (tan body with yellow fenders) thereby making it clear that the bus is not a working school bus. The yellow is actually a Toyota FJ color, not SBY.

I thought the Morris would be a quick fix but it took me a year to finally geterdone --but what fun to drive! Jack

This is the MM as I bought it.

The Tracker had accident damage but drove just fine.

I kept the chassis, drive line, floor pan and interior.

The MM had heavy accident damage to the rear floor area and plenty of rust in the floor --so I cut it out. I hung what was left from the rafters of my garage on come alongs and began work.

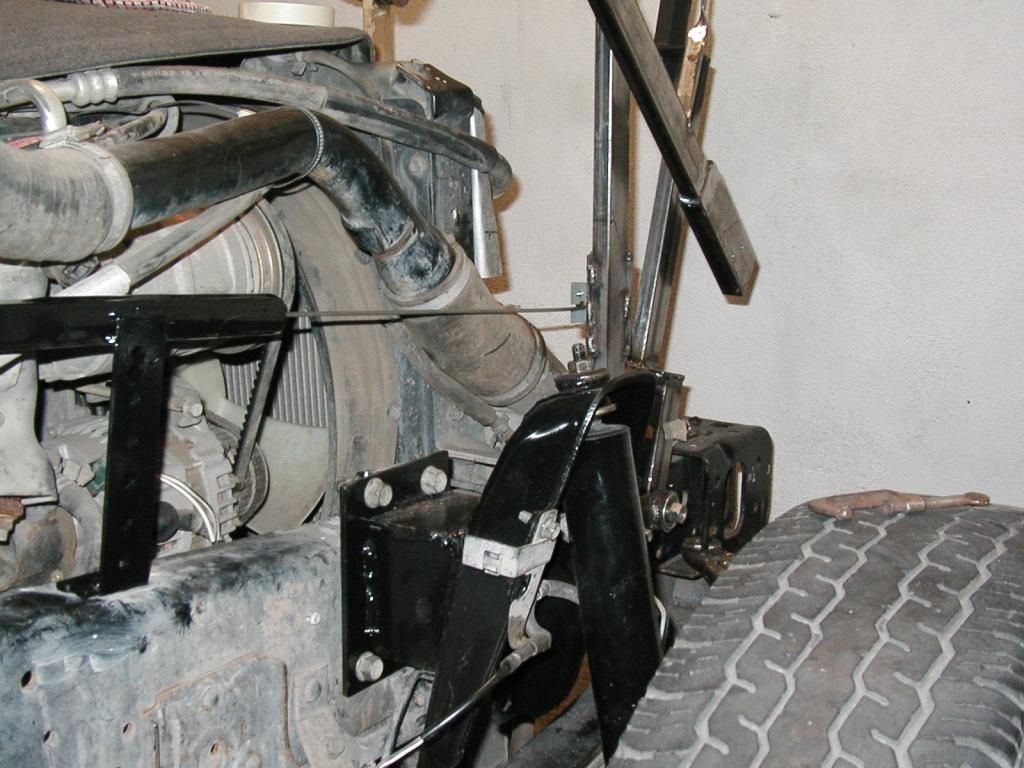

I built a tube frame for the MM so I could bolt it to the Tracker frame.

Next I fit the Tracker floor into the MM.

I had to narrow the seat frames to fit the MM.

I also made a new replacement rear floor for the MM so it would look "original"

I had to reverse some of the sheet metal on the MM dash and build a new trans hump for the 4X4.v

The wood was next. I bought a "kit" from England--nothing more than loose fitting scraps--I sure learned a lot!

I was able to restore the interior structural wood.

Next came reassembly and paint. The rear fenders didn't look good so I reduced the opening and added 2" width.

[b]

[b]

[b][b] First show. I've just added the tow bar.